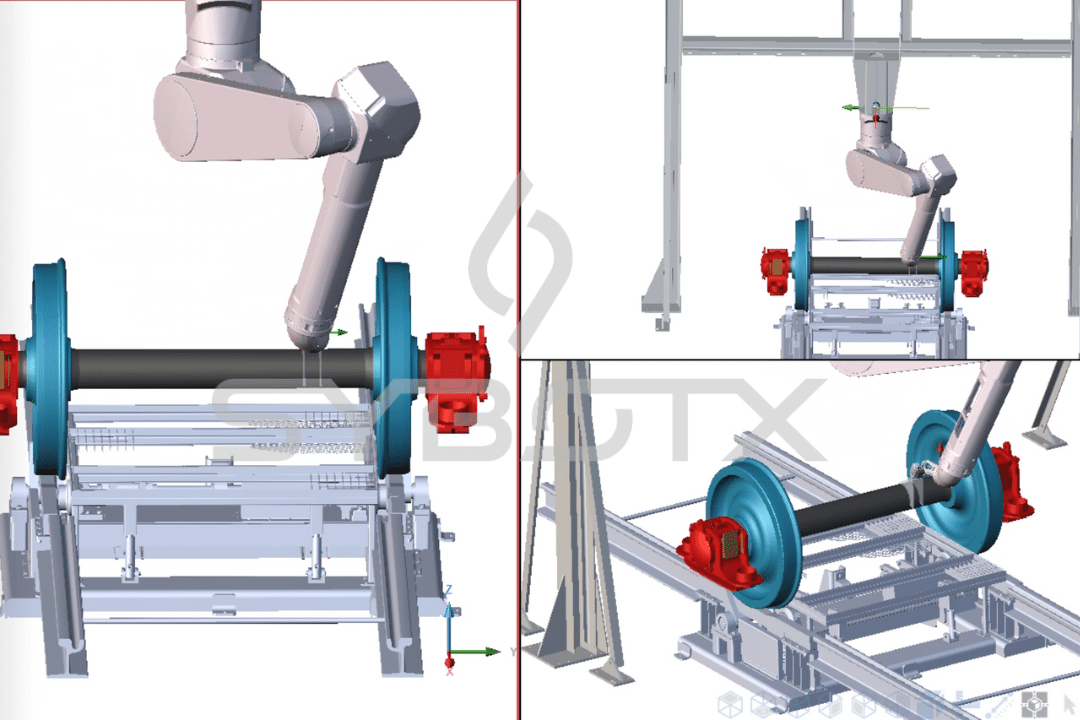

Study and commissioning of a robotic station for painting train axles, with the aim of recycling them.

Axle Revalorization :

The client wanted to refurbish train axles to make them reusable, thus contributing to the recycling of these expensive and relatively uninnovative components.

Our mission was to spray anti-corrosion product onto the axles using a robot, targeting different parts of the wheels while accounting for variations in diameter.

The client’s objective was to offer these reconditioned axles to train manufacturers and designers in the global market, ensuring product durability and safety.

Functioning :

Equipment Used :

Staubli TX250 Paint Robot.

SC8C Controller.

Automatic Airless Sprayer.

The axle is conveyed into the robotic station. The axle comes to a stop and then rotates. The robot follows its application path based on the model. The axle is then removed.

Conclusion :

The automation and robotization of the spraying process have reduced product consumption, thanks to the precise movements of the industrial robot, leading to consistent and reproducible results.

By avoiding the oxidation process, these axles remain in good condition for a longer period, ensuring the safety and performance of rail vehicles.

This robotic station has also provided a rapid and efficient return on investment compared to manual spraying methods.

In line with our commitment to the environment, SybotX is proud to have led this robotic project that enables the renovation of railway axles.