Objective :

To respond to the support request of an integrator, with the aim of defining technical aspects, conducting studies and robotic programming, and fine-tuning the robotic cell.

Functioning :

Equipment Used :

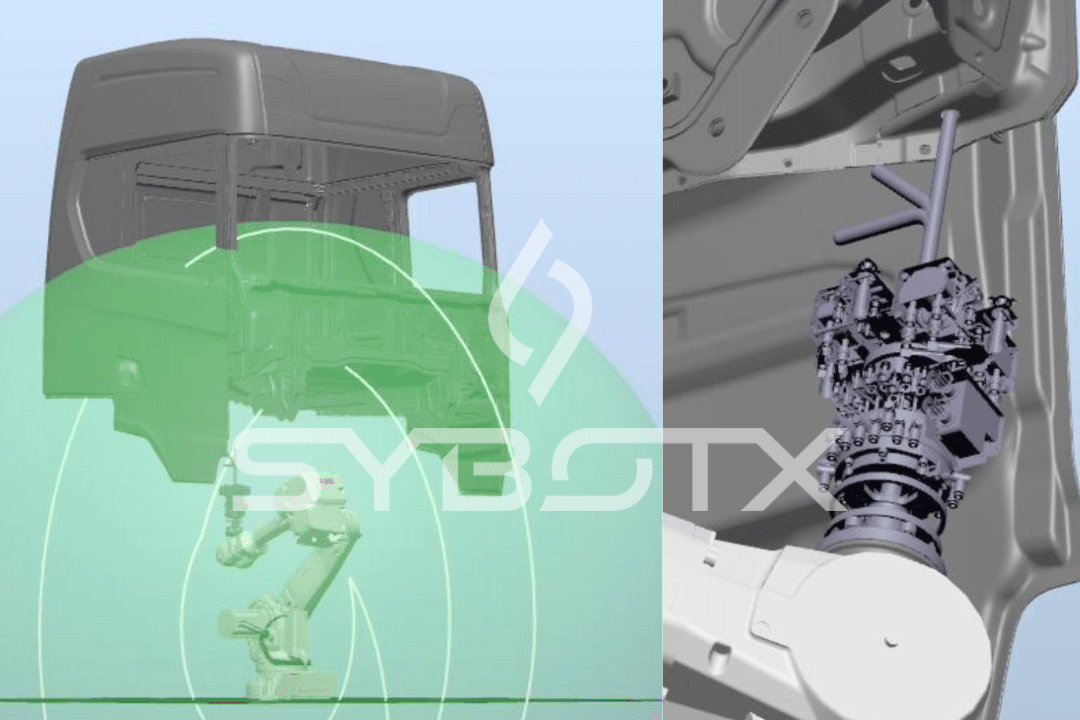

- 2 ABB IRB 4600 robots.

- 2D vision system.

- Sprayer equipped with 4 different interchangeable nozzles.

The vehicle enters the station via a conveyor. The vision system analyzes any potential misalignment and transmits this information to the robot. The robot then adjusts its trajectories accordingly to apply wax in the vehicle’s cavities. No manual intervention is required.

Once this step is completed, the vehicle is safely evacuated, having received a precise and uniform wax treatment.

Conclusion :

The robotic system along with the 2D vision have enhanced the quality of the wax application process, thus reducing the risks of corrosion and increasing the durability of the vehicle cabins.

Our team’s expertise in utilizing ABB robots, our mastery of robotic vision technologies, and our international capabilities were crucial for the success of this project.

SybotX positions itself as a reliable and skilled partner, providing tailor-made solutions that meet the specific needs of each client.