Description :

Execution of an innovative project aimed at India and China, aiming to optimize the galvanization process. The goal is to implement a robotic system for cleaning the zinc bath in which steel sheets are immersed.

Initially, the process was carried out manually by operators, exposing them to significant risks such as burns and intoxication related to the handling of chemical products.

How it works :

Equipment used :

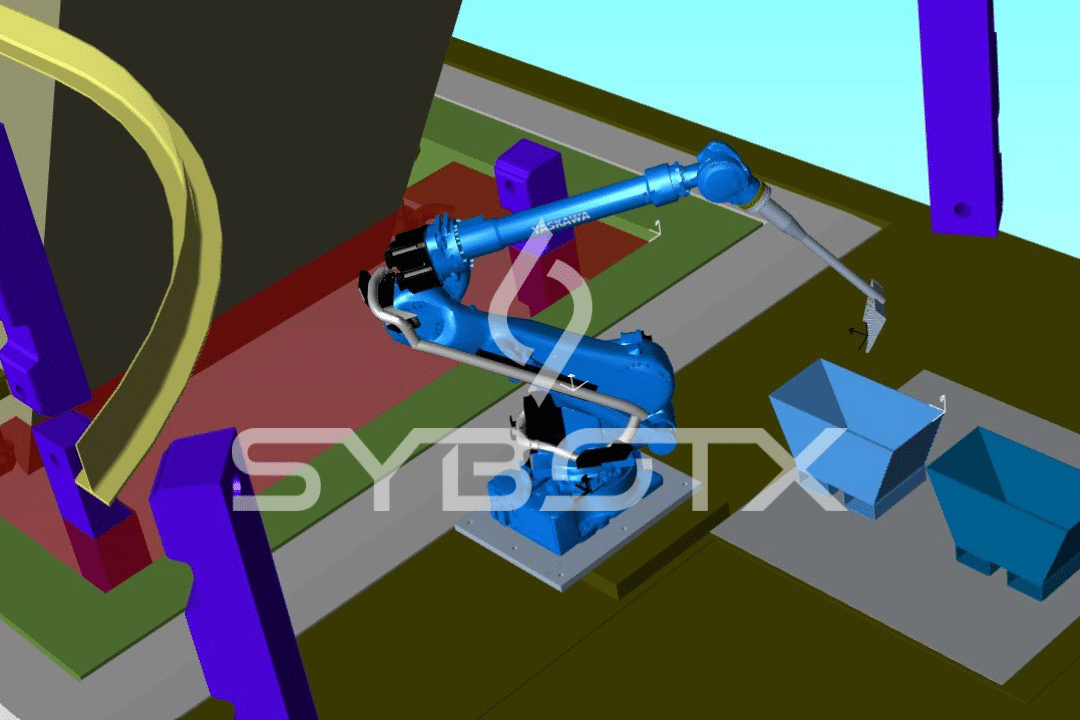

Robot Yaskawa GP-180.

YRC 1000 Controller.

The automated station integrates a Yaskawa robot. It allows skimming and removing ash from the zinc bath, as well as collecting zinc samples.

To facilitate equipment use, a “tool holder” module has been specifically developed. It incorporates various sensors allowing automatic tool changes according to the current sequence.

To avoid any risk of interaction with hazardous elements, the operator triggers robot cycles as needed via a human-machine interface (HMI).

Conclusion :

This robotic solution represents much more than simple automation.

It signifies a complete transformation of operations, providing tangible benefits in terms of productivity, quality, and, above all, safety.