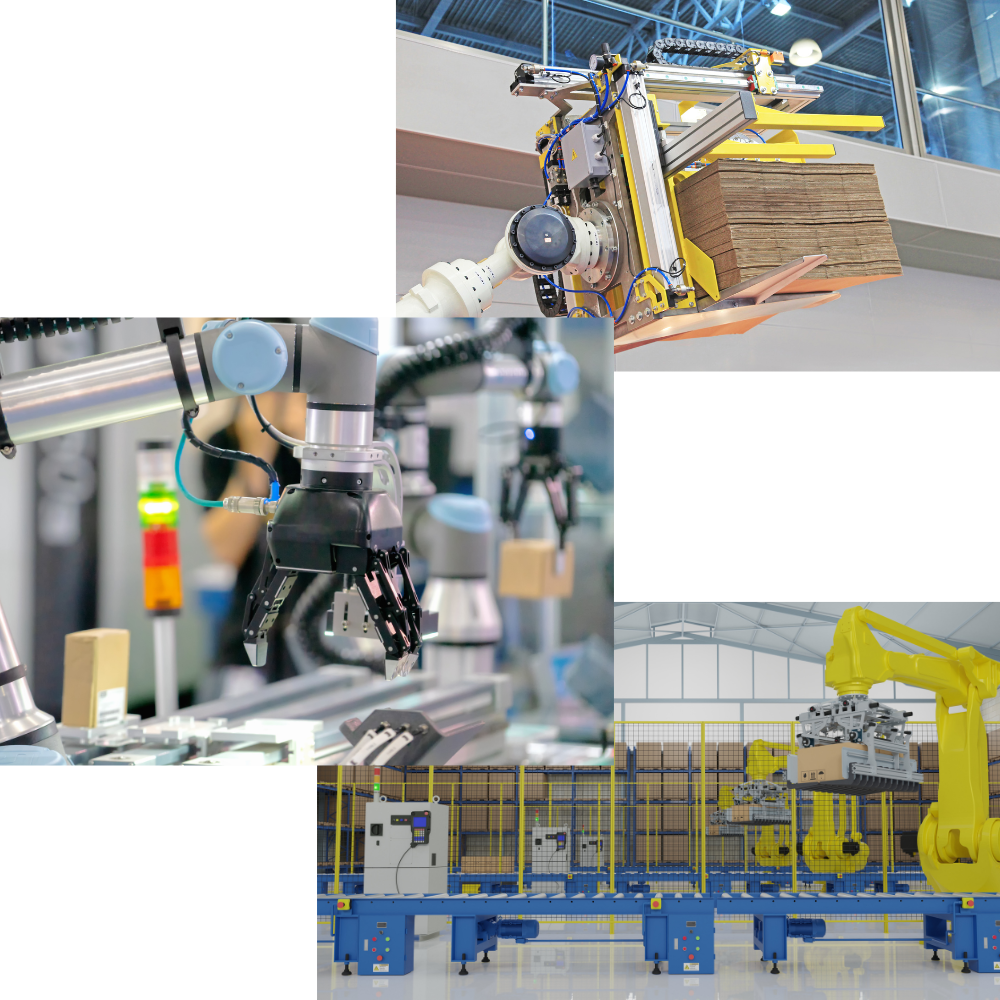

PICK & PLACE - BULK - PALLETIZING - VISION

PRECISION

VISION

GRIPPING

ROBOTIC MANIPULATION PROCESS

In many industrial sectors, repetitive tasks lead to musculoskeletal disorders (MSDs), particularly due to the handling of heavy loads.

This is why it is essential to optimize your industrial operations by automating your production lines.

At SybotX, we are committed to studying, designing and integrating agile solutions that perfectly meet your needs.

We guarantee optimal automation of your industrial processes.

PRINCIPLES OF HANDLING SYSTEMS

PROGRAMMABLE AND AUTOMATED HANDLING

The manipulation of elements is the primary principle of standard process systems in industrial robotics.

Handling robots meet two major challenges for your industrial activity.

Safety: Protecting your teams from the strain associated with repetitive movements or heavy lifting.

Profitability: An effective solution that performs quick tasks over extended periods.

VERSATILITY AND ADAPTABILITY

Thanks to their modular design and interchangeable grippers , industrial robots can be quickly reconfigured to perform various operations without requiring major modifications.

This flexibility gives companies a competitive advantage , allowing them to respond effectively to fluctuations in demand and optimize the use of their robotic resources.

VARIOUS TYPES OF MANIPULATOR ROBOTS

The number of joints in a manipulator robot defines its degrees of freedom, the configuration of its working envelope, and its application possibilities.

These characteristics determine the robot’s classification:

- Cartesian: 1 to 3 axes providing linear movements.

- SCARA: 4 axes enabling precise lateral movements.

- Delta: made up of 3 parallelograms, executing rapid planar movements.

- Articulated: 6 axes or more, allowing for complex movements.

THE DIFFERENT TYPES OF STANDARD MANIPULATION

PICK AND PLACE

Pick and place in industrial robotics involves grasping objects from a designated location and then moving them to another location accurately and efficiently.

Equipped with various sensors, such as vision and linear grippers, the manipulation operation reduces errors and the costs associated with human labor.

STRIPPING & PINNING

Picking and pinning in industrial robotics involves separating and pinning bulk items , such as parts or food products, from containers or bags.

Equipped with arms and sensors to grip and handle products, the aim of the process is to improve chain efficiency , minimise errors and optimise stock management .

PALETISATION / DEPALETISATION

Automating the loading and unloading processes of products reduces reliance on manual labor, optimizes efficiency, and minimizes errors.

With robots and sensors, loads are handled precisely and safely, enhancing productivity and streamlining logistics operations.

2D AND 3D VISION

Robotics processes, integrating 2D and/or 3D vision, allow robots to precisely locate , manipulate and control objects .

By having detailed spatial information from vision, gripping and positioning sensors, robots can work reliably and efficiently, improving overall operational performance.

ROBOTS DEDICATED TO STANDARD MANIPULATION

There are several brands of robots, the best known of which are FANUC, ABB, YASKAWA, STAUBLI, KUKA, KAWASAKI…

SybotX , your robotic engineering office specializing in spraying and deposition, collaborates and works with many brands.